When choosing hinges for a door, designers, architects, and hardware specifiers often weigh the pros and cons of invisible hinges and butt hinges. Both types offer different aesthetic, functional, and installation trade-offs. For high-end doors, especially those needing flush, clean lines or concealed functionality, understanding which hinge type is better for your project is crucial.

What Are Invisible Hinges and Butt Hinges?

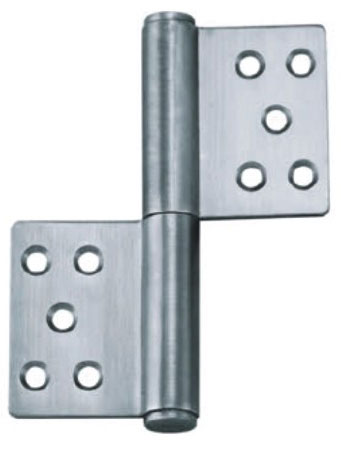

Butt hinges (or mortise hinges) are the classic pivot hinge: two rectangular leaves, one fixed to the door edge and one to the frame, connected by a central pin. They are visible from the side when the door is open or closed (though some designers select concealed leaf styles). Butt hinges are versatile and widely used in residential, commercial, and architectural settings.

Invisible hinges (also called concealed hinges, hidden hinges, or pivot mortise hinges) are designed so that when the door is closed, the hinge is completely hidden from view. The hinge mechanism is installed inside the door edge and frame. The hinge arms allow smooth pivoting, often in both directions, and a flush aesthetic with no visible hardware lines. Invisible hinges are particularly popular in high-end wood joinery, custom cabinetry, and architectural interior doors.

Invisible Hinge vs. Butt Hinge: Which Is Better for Your Door?

To decide which hinge type is better for your door, consider the following factors:

Aesthetic & Visual Impact

Invisible hinges deliver a sleek, minimalistic appearance with no exposed hardware lines — which is ideal for modern, flush, high-end doors.

Butt hinges are more traditional; though you can choose decorative or minimal styles, some silhouette is still visible.

Load Capacity & Durability

High-quality invisible hinges can support heavy doors (solid wood, metal, glass) when properly sized and installed.

Butt hinges have long been proven in heavy-duty and high-traffic environments with rugged performance over decades.

Concealment & Clean Lines

For door systems where the hinge should not interrupt the clean line or become part of the visual vocabulary, invisible hinges are favorable.

Butt hinges, even in slim form, may still interrupt the aesthetic continuity or require trimming or cover plates.

Adjustment & Fine Tuning

Many invisible hinges incorporate multi-axis adjustment (height, depth, and sidelong) to fine-tune door alignment after installation.

Butt hinges typically require manual shimming or mortise trimming to adjust alignment.

Installation Complexity & Cost

Invisible hinges often require precise routing, deeper mortises, and calibration to meet flush tolerance. Installation labor and tolerances are higher.

Butt hinges are more straightforward to install, require shallower mortises, and experienced carpenters commonly install them.

Maintenance & Serviceability

Invisible hinges—when of high quality—are low maintenance, but replacement or servicing may require more disassembly since the hinge is embedded.

Butt hinges are easier to access, lubricate, or replace in case of wear.

Resistance to Corrosion & Stability

Because hidden hinges are more enclosed, their surface treatments and rust resistance must be excellent to maintain long-term stability.

Butt hinges, though exposed, can be more easily inspected and maintained.

When to Choose Invisible Hinges?

If your project emphasizes seamless aesthetics, modern minimalism, or you want truly flush surfaces without visible hardware, invisible hinges are often the superior choice. They're perfect for:

● High-end wooden doors, veneers, or flush panels

Interior doors with continuous wall planes

● Glass-framed doors or pivot doors, where clean lines are critical

● Projects where concealed hardware brings a premium, refined finish

The invisible hinge must be of high quality to ensure stability, durability, and corrosion resistance—especially in demanding environments.

When to Choose Butt Hinges?

Butt hinges remain a trusted, versatile option when you need:

● Lower cost or faster installation

● Proven durability under heavy traffic

● Easier maintenance or replacement

● Traditional or decorative aesthetics where visible hardware is acceptable

● Simpler manufacturing or field installation tolerances

In many standard residential, commercial, or retrofit cases, butt hinges are still a sensible and reliable choice.

Practical Tips When Choosing Door Hinges

When selecting between invisible hinges and butt hinges, here are actionable tips to guide your decision and specification:

Door Weight & Size Matching: Always select hinge models rated above the anticipated door weight (plus allowances). Invisible hinge manufacturers will publish load limits; butt hinges come in standard load classes.

Number of Hinges and Placement: Heavy doors may require three or more hinges. Invisible hinges may demand more careful spacing to maintain smooth motion. For butt hinges, align with standard structural recommendations.

Material & Finish Compatibility: Choose hinge materials that match or complement other hardware finishes (e.g., stainless, brass, powder-coated). For invisible hinges, ensure plating or coating holds up in concealed environments.

Tolerance Coordination: Invisible hinges require tighter tolerances in your door and frame construction. Allow sufficient gap, routing clearance, and door geometry precision. Butt hinges are more forgiving in conventional carpentry.

Hinge Adjustment Features: If fine adjustment is important (to avoid door sagging over time), favor invisible or premium butt hinges with adjustability in three axes.

Maintenance Planning: In high-humidity, corrosive environments, or heavy use, schedule periodic inspection or lubrication. For hidden hinges, specify models tested for high cycle counts and corrosion salts.

Cost-Benefit Evaluation: The premium for invisible hinges (in parts, fabrication, installation) must be balanced by the design value you reap. In more utilitarian doors, a well-specified butt hinge often offers better ROI.

Sunda Advantage for Both Door Hinge Types

Sunda specializes in both invisible hinges and butt hinges, providing tailored solutions to meet design demands. Here's what sets us apart:

100% Quality and Rust-Resistance Guarantee: Every component undergoes a thorough inspection to ensure that its performance and corrosion resistance remain stable over time.

Precision Control via Visual Production Management: Our internal management system ensures consistency and traceability in every batch.

Custom Engineering Capability: Whether your door requires a unique hinge dimension, special material or finish, or integrated features, we can deliver the customization you need.

On-time Delivery Assurance: With robust production capacity and process control, we meet deadlines reliably.

Compensation Commitment: In the unlikely event of quality issues, we back each project with 100% compensation—you can trust your investment is safe.

Long-Term Partnership Focus: Choosing Sunda means selecting a responsive, dependable ally for your hardware strategy and supply chain.

We manufacture both invisible hinges and traditional butt hinges to help you compare and decide which is better for your specific door application.

Conclusion

The decision between invisible hinges and butt hinges ultimately depends on your design goals, budget, installation environment, and maintenance expectations. If your priority is achieving perfect flush aesthetics and a refined, hardware-free look, invisible hinges (of high quality) shine. If your priority is simplicity, durability, ease of service, or cost efficiency, butt hinges might win.

Sunda supplies both door hinge types, offers customization, and delivers the solution that fits your door, your project, and your long-term goals. Feel free to contact us at info@sundahardware.com for your custom needs.

_31221.png)